Moisture in buildings has been a frequent, unpleasant and ancient presence as old as the history of civilization and the problem of humidity and its elimination or removal from walls has always been one of the main points in the maintenance of buildings.

In the 14th chapter of the “Leviticon” (* 1), cited in the classic text “Renovation of damp rooms” (* 2), the “common sense prescriptions” are reported to avoid or reduce the onset of the “humidity” problem.

Herodotus, in 420 BC, reports, complaining about the presence of white stripes and spots of humidity, visible on the walls and plasters of greek temples.

Only between 1800 and 1900 some scholars of “building affairs”, have ventured into serious investigations in search of solutions to the problem of humidity in buildings and with the advent of industrialization things started to improve.

Below we cite three different examples of technologies, which we can define of “historical interest”, aimed at the “search for the possible solution to the problem” applied in hundreds of buildings, which if they have not fully solved the aforementioned phenomena have certainly traced the way to the use of new technologies and innovative products.

(* 1) Third book of the Jewish Torah and the Christian Bible, consisting of 27 chapters, written in Hebrew, containing religious and social laws, for the use of priests and Levites (around 1200 BC).

(* 2) “Restoration of wet rooms” by the engineers Giovanni and Ippolito Massari, published in the early 1980s by Hoepli.

Knapen drainage siphon (atmospheric siphon system)

The technique of draining siphons of Knapen, from the name of the inventor who first experimented them (Achille Knapen in the early 1900s) also known as the “atmospheric siphon” system, is based on the principle that damp walls can dry out by increasing the aeration and the circulation of air inside them.

Knapen siphons are manufactured items originally made of porous earthenware and made up of hollow cylindrical or prismatic elements, between 10 and 50 cm long, with a longitudinal blind internal hole with a diameter of about 3 cm. Over time they have been produced in various geometries, with a triangular, hexagonal section and in various other shapes and with different materials, such as stainless steel and plastic.

According to Knapen, the drier and lighter outside air enters the siphon replacing the heavier damp inside air which is expelled from the masonry. This exchange of air inside the siphon should also generate an increase in evaporation inside the wall.

Although the system is fast, inexpensive, does not require professional installers and can be applied with the “do it yourself” method, it has never been possible to fully demonstrate its positive and beneficial effect on walls.

Perimeter cavedium

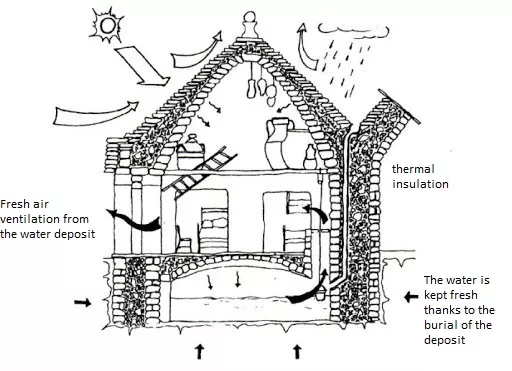

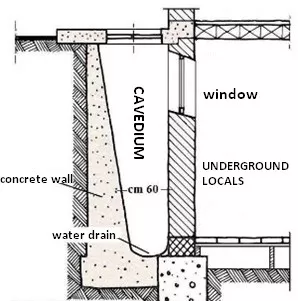

The perimeter cavedium (also called ventilated underground cavity) is an underground corridor, built externally to the perimeter of the building to separate the ground from the foundations and circulate the incoming air from the grids inserted at its top, thus promoting the expulsion of underground moisture.

At the same time, the brightness in the underground rooms is improved, favoring the positioning of cable ducts and various systems.

It is certainly an excellent way to remove the soil and the humidity it carries from the perimeter wall, but often it is not feasible and, when feasible, it has a very high cost for its manufacture without any certainty of eliminating the problem of capillary rising from foundations

Mechanical cutting of the walls above the sidewalk

The process of mechanically cutting of the walls consists, literally, in a cutting operation of the entire wall section just above the sidewalk. This operation completely isolates the masonry from the rest of the load-bearing structure located below the walking surface. It is carried out with a special circular diamond saw that reaches a depth equal to the total thickness of the masonry, followed by the forced insertion of a specific insulator into the space created (usually it is non-corrodible steel or resinous slabs with high compressive strength).

The clear advantages of this method are therefore found in the barrier that is created in such a way as to physically defend the structure from rising damp, with barrier materials that are very resistant to wear and effective even against any type of salt.

However, it is necessary to take into account the invasiveness of the method, not only polluting and noisy, but also expensive, and with high intervention times, and for which special equipment and specially qualified workers are needed.

In addition, the technique is difficult to apply in the case of masonry with high thicknesses, if not impossible for underground, basement rooms or with walls against the ground. Furthermore, the cut represents a real trauma for the whole structure and can compromise, if poorly constructed, the aesthetics of the masonry and the static nature of the artefacts, a particularly significant problem in seismic risk areas. The risk of partial subsidence is very high, especially if it concerns rubble masonry, as well as that of injuries and detachments of the plasters due to cutting vibrations; in addition, there is the real possibility of damaging the under-track elements such as the electrical or water system.